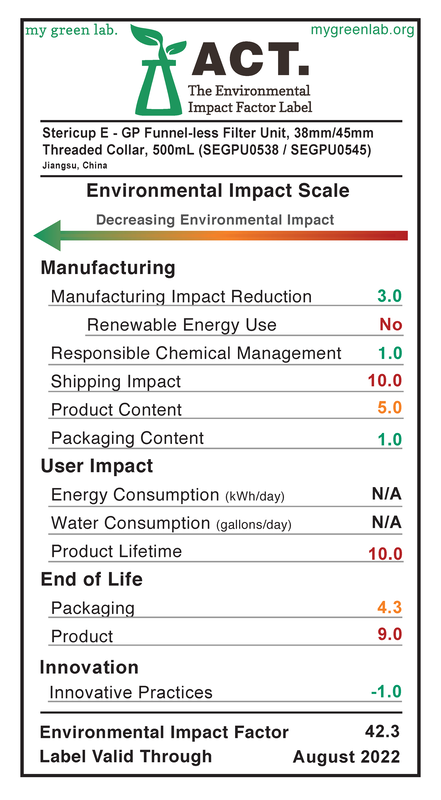

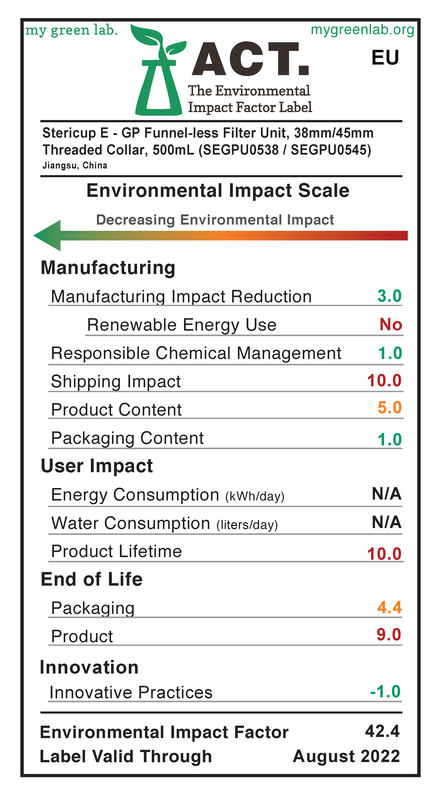

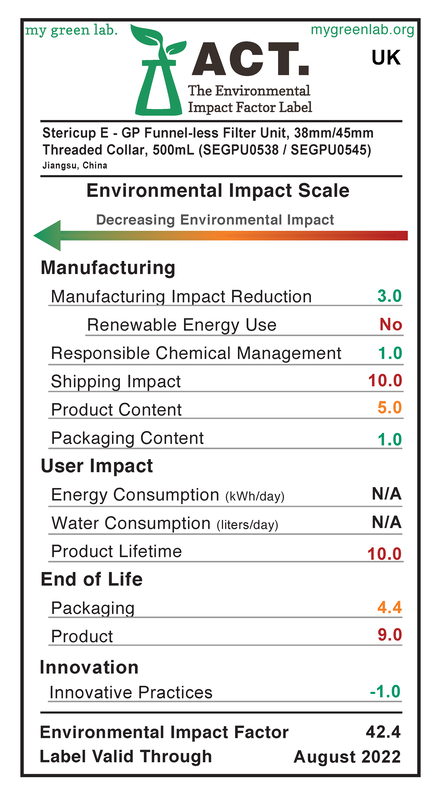

MilliporeSigma Stericup E - GP Funnel-less Filter Unit, 38mm/45mm Threaded Collar, 500mL (SEGPU0538/SEGPU0545) US/EU/UK

Additional Information about Stericup E - GP Funnel-less Filter Unit, 38mm/45mm Threaded Collar, 500mL (SEGPU0538 / SEGPU0545) US/EU/UK

Manufacturing Impact Reduction

This category evaluates the steps that have been taken to reduce energy consumption, water consumption, and waste generation at the manufacturing facility where the MilliporeSigma product is produced. MilliporeSigma has implemented energy and water saving measures at the manufacturing facility where the product is produced.

Renewable Energy Use

The manufacturing facility where the MilliporeSigma product is produced does not utilize any renewable energy.

Responsible Chemical Management

The score of 1 in this category reflects proof of an Environmental Health and Safety program, and verification that the products do not contain CMRs, PBTs, GHS Category 1 Hazards, GS BM-1 chemicals, GS LT-1 chemicals, or red list chemicals above the reporting threshold.

Shipping Impact

The MilliporeSigma products are manufactured in Jiangsu, China. The US and EU / UK markets are serviced via MilliporeSigma's distribution centers in Massachusetts, USA and Strasbourg, France, respectively.

Product Content

The MilliporeSigma Stericup E 500mL (38mm and 45mm threaded collars) was dematerialized relative to the GP Sterile Vacuum Filtration System 500mL by over 20% by weight.

Packaging Content

The MilliporeSigma Stericup E 500mL (38mm and 45mm threaded collars) packaging contains sustainable content. The box and box dividers contain 100% FSC-certified recycled content. The MilliporeSigma Stericup E 500mL (38mm and 45mm threaded collars) packaging was dematerialized relative to the GP Sterile Vacuum Filtration System 500mL by 17% by weight.

Energy Consumption

The MilliporeSigma product does not use any energy in its use phase.

Water Consumption

The MilliporeSigma product does not use any water in its use phase.

Lifetime Rating

The MilliporeSigma product is disposable with a short use-phase.

Packaging End-of-Life

The MilliporeSigma products are packaged using corrugated cardboard and HDPE/LDPE bags. The corrugated cardboard packaging materials are readily recyclable in the US, EU and UK markets. In the US, the HDPE/LDPE bag are recyclable but the infrastructure is not readily available. In the EU and UK, the HDPE/LDPE bags are either sent to a waste-to-energy facility, recycled, or sent to landfill, depending on the specific market. MilliporeSigma also provides education to end-users regarding how to dispose of or recycle the packaging.

Product End-of-Life

The MilliporeSigma product is typically considered bio-hazardous waste and is sent to landfill or incineration at end of life. Per applicable policy, this is the only option. MilliporeSigma offers education to the end-user on how to dispose of the product and recycle it depending on the application.

Innovation

MilliporeSigma's dematerialization of the product and packaging materials has allowed more product to be shipped per pallet. By increasing the amount of product that can be shipped per pallet, MilliporeSigma has effectively reduced the environmental impact intensity, measured as impact per product, associated with the transportation of the product.

This category evaluates the steps that have been taken to reduce energy consumption, water consumption, and waste generation at the manufacturing facility where the MilliporeSigma product is produced. MilliporeSigma has implemented energy and water saving measures at the manufacturing facility where the product is produced.

Renewable Energy Use

The manufacturing facility where the MilliporeSigma product is produced does not utilize any renewable energy.

Responsible Chemical Management

The score of 1 in this category reflects proof of an Environmental Health and Safety program, and verification that the products do not contain CMRs, PBTs, GHS Category 1 Hazards, GS BM-1 chemicals, GS LT-1 chemicals, or red list chemicals above the reporting threshold.

Shipping Impact

The MilliporeSigma products are manufactured in Jiangsu, China. The US and EU / UK markets are serviced via MilliporeSigma's distribution centers in Massachusetts, USA and Strasbourg, France, respectively.

Product Content

The MilliporeSigma Stericup E 500mL (38mm and 45mm threaded collars) was dematerialized relative to the GP Sterile Vacuum Filtration System 500mL by over 20% by weight.

Packaging Content

The MilliporeSigma Stericup E 500mL (38mm and 45mm threaded collars) packaging contains sustainable content. The box and box dividers contain 100% FSC-certified recycled content. The MilliporeSigma Stericup E 500mL (38mm and 45mm threaded collars) packaging was dematerialized relative to the GP Sterile Vacuum Filtration System 500mL by 17% by weight.

Energy Consumption

The MilliporeSigma product does not use any energy in its use phase.

Water Consumption

The MilliporeSigma product does not use any water in its use phase.

Lifetime Rating

The MilliporeSigma product is disposable with a short use-phase.

Packaging End-of-Life

The MilliporeSigma products are packaged using corrugated cardboard and HDPE/LDPE bags. The corrugated cardboard packaging materials are readily recyclable in the US, EU and UK markets. In the US, the HDPE/LDPE bag are recyclable but the infrastructure is not readily available. In the EU and UK, the HDPE/LDPE bags are either sent to a waste-to-energy facility, recycled, or sent to landfill, depending on the specific market. MilliporeSigma also provides education to end-users regarding how to dispose of or recycle the packaging.

Product End-of-Life

The MilliporeSigma product is typically considered bio-hazardous waste and is sent to landfill or incineration at end of life. Per applicable policy, this is the only option. MilliporeSigma offers education to the end-user on how to dispose of the product and recycle it depending on the application.

Innovation

MilliporeSigma's dematerialization of the product and packaging materials has allowed more product to be shipped per pallet. By increasing the amount of product that can be shipped per pallet, MilliporeSigma has effectively reduced the environmental impact intensity, measured as impact per product, associated with the transportation of the product.