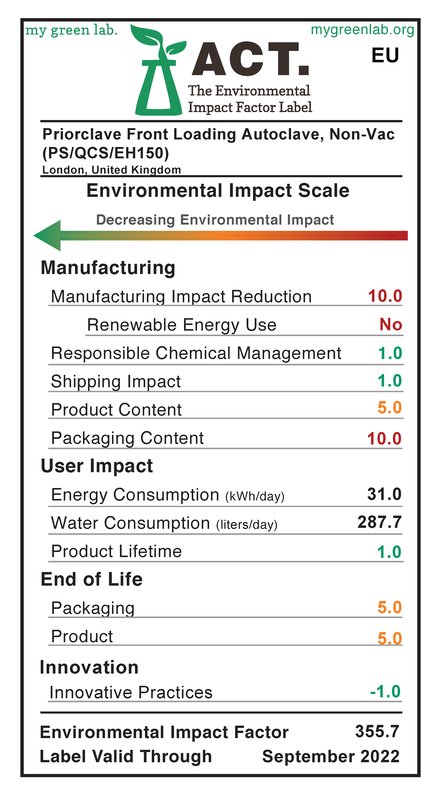

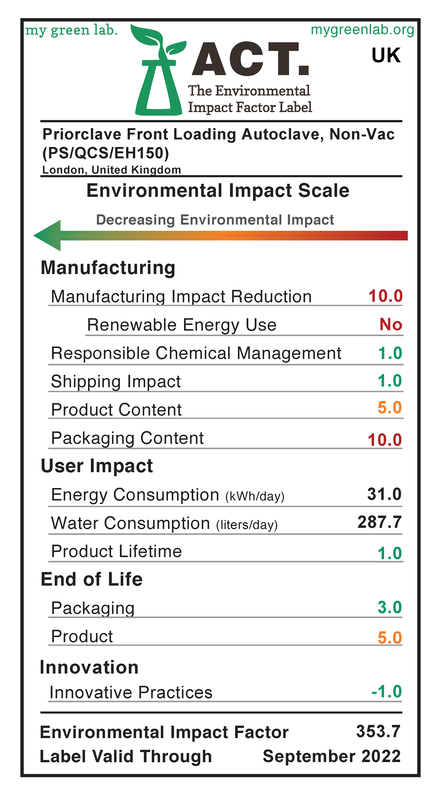

Priorclave Front Loading Autoclave, Non-Vac (PS/QCS/EH150) EU/UK

Additional Information about Priorclave Front Loading Autoclave, Non-Vac (PS/QCS/EH150) EU/UK

Manufacturing Impact Reduction

The London, UK manufacturing facility where the Priorclave autoclave is produced has not implemented any energy, water, or waste reduction measures in the past five years.

Renewable Energy Use

The London, UK manufacturing facility where the Priorclave autoclave is produced does not use any renewable energy to produce the product.

Responsible Chemical Management

The score of 1 in this category reflects proof that Priorclave has implemented an Environmental Management System (EMS) at its London, UK manufacturing facility where the autoclave is produced. The EMS covers the management and communication of hazardous chemistry throughout the value chain and within the manufacturing process.

Shipping Impact

The Priorclave autoclave is manufactured in London, United Kingdom. The EU and UK markets are both serviced from the manufacturing facility.

Product Content

The steel sheets used in the Priorclave autoclave contains over 80% recycled content. This results in 30-60% recycled content in the autoclaves, depending on the specific model.

Packaging Content

EU: For the EU market, the Priorclave autoclave is packaged with bubble wrap, plastic stretch film, and a wooden crate. None of the packaging materials used to package and ship the Priorclave autoclave to the EU market contain any sustainable content.

UK: For the UK market, the Priorclave autoclave is packaged with bubble wrap which does not contain any sustainable content.

Energy Consumption

The Priorclave autoclave consumes energy during its use phase. The daily energy consumption value assumes that the product is run for six cycles (non-vacuum) over a twelve-hour period during a typical use case, with the unit in standby mode for the remaining twelve hours of day.

Water Consumption

The Priorclave autoclave consumes water during its use phase. The daily water consumption value assumes that the product is run for six cycles (non-vacuum) over a twelve-hour period during a typical use case, with the unit in standby mode for the remaining twelve hours of day.

Lifetime Rating

Priorclave offers a 10-year warranty for its products. However, the autoclaves have a verified lifetime expectancy of greater than 25 years.

Packaging End-of-Life

EU: Priorclave uses oxo-biodegradable bubble wrap, plastic stretch film, and a wooden crate to package and ship its products with the EU market. The oxo-biodegradable bubble wrap has been tested by the supplier to be in conformance with ASTMD6954 and has a dwell time of 9-12 months followed by a micro-fragmentation period of 6-12 months. The crate is readily recyclable while the plastic stretch film is either landfilled, recycled or incinerated depending on available infrastructure.

UK: Priorclave uses oxo-biodegradable bubble wrap to package and ship its products within the UK market. The oxo-biodegradable bubble wrap has been tested by the supplier to be in conformance with ASTMD6954 and has a dwell time of 9-12 months followed by a micro-fragmentation period of 6-12 months.

Product End-of-Life

The Priorclave autoclave is primarily made out of copper and stainless steel. At the product's end-of-life, these materials are readily recyclable in the US market; in the EU and UK markets, the product is disposed of according to the Waste Electrical and Electronic Equipment Directive (WEEE Directive 2012/19/EU).

Innovation

Priorclave has engaged with a carrier service that participates in a carbon offset program to distribute the autoclaves to the end user. As of February 2020, the carrier achieved 200 Certified Emission Reductions (CERs) which equates to an offset of 200 tonnes of carbon dioxide.

The London, UK manufacturing facility where the Priorclave autoclave is produced has not implemented any energy, water, or waste reduction measures in the past five years.

Renewable Energy Use

The London, UK manufacturing facility where the Priorclave autoclave is produced does not use any renewable energy to produce the product.

Responsible Chemical Management

The score of 1 in this category reflects proof that Priorclave has implemented an Environmental Management System (EMS) at its London, UK manufacturing facility where the autoclave is produced. The EMS covers the management and communication of hazardous chemistry throughout the value chain and within the manufacturing process.

Shipping Impact

The Priorclave autoclave is manufactured in London, United Kingdom. The EU and UK markets are both serviced from the manufacturing facility.

Product Content

The steel sheets used in the Priorclave autoclave contains over 80% recycled content. This results in 30-60% recycled content in the autoclaves, depending on the specific model.

Packaging Content

EU: For the EU market, the Priorclave autoclave is packaged with bubble wrap, plastic stretch film, and a wooden crate. None of the packaging materials used to package and ship the Priorclave autoclave to the EU market contain any sustainable content.

UK: For the UK market, the Priorclave autoclave is packaged with bubble wrap which does not contain any sustainable content.

Energy Consumption

The Priorclave autoclave consumes energy during its use phase. The daily energy consumption value assumes that the product is run for six cycles (non-vacuum) over a twelve-hour period during a typical use case, with the unit in standby mode for the remaining twelve hours of day.

Water Consumption

The Priorclave autoclave consumes water during its use phase. The daily water consumption value assumes that the product is run for six cycles (non-vacuum) over a twelve-hour period during a typical use case, with the unit in standby mode for the remaining twelve hours of day.

Lifetime Rating

Priorclave offers a 10-year warranty for its products. However, the autoclaves have a verified lifetime expectancy of greater than 25 years.

Packaging End-of-Life

EU: Priorclave uses oxo-biodegradable bubble wrap, plastic stretch film, and a wooden crate to package and ship its products with the EU market. The oxo-biodegradable bubble wrap has been tested by the supplier to be in conformance with ASTMD6954 and has a dwell time of 9-12 months followed by a micro-fragmentation period of 6-12 months. The crate is readily recyclable while the plastic stretch film is either landfilled, recycled or incinerated depending on available infrastructure.

UK: Priorclave uses oxo-biodegradable bubble wrap to package and ship its products within the UK market. The oxo-biodegradable bubble wrap has been tested by the supplier to be in conformance with ASTMD6954 and has a dwell time of 9-12 months followed by a micro-fragmentation period of 6-12 months.

Product End-of-Life

The Priorclave autoclave is primarily made out of copper and stainless steel. At the product's end-of-life, these materials are readily recyclable in the US market; in the EU and UK markets, the product is disposed of according to the Waste Electrical and Electronic Equipment Directive (WEEE Directive 2012/19/EU).

Innovation

Priorclave has engaged with a carrier service that participates in a carbon offset program to distribute the autoclaves to the end user. As of February 2020, the carrier achieved 200 Certified Emission Reductions (CERs) which equates to an offset of 200 tonnes of carbon dioxide.