Eppendorf CryoCube F740hiW ULT Freezer

Additional Information about Eppendorf CryoCube F740hiw ULT Freezer

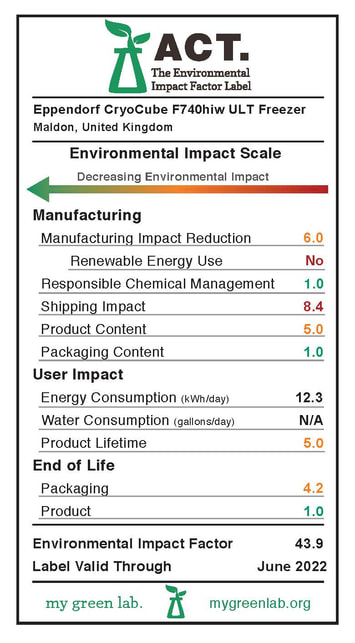

Manufacturing Impact Reduction

This category evaluates the steps that Eppendorf has taken to reduce energy consumption, water consumption, and / or waste generation at the manufacturing facility at which the Eppendorf CryoCube® F740hiw ULT freezer is made. The score of 6 in this category reflects Eppendorf’s efforts to reduce energy consumption at the facility.

Renewable Energy Use

The manufacturing facility at which the Eppendorf CryoCube® F740hiw ULT freezer is made does not use renewable energy.

Responsible Chemical Management

The score of 1 in this category reflects proof of an Environmental Health and Safety program and verified ISO 140001 processes. The refrigerants in the Eppendorf CryoCube® F740hiw ULT freezer were also found to be free of CMRs, PBTs, HCFCs, CFCs, GHS Category 1 Hazards, and red list chemicals.

Shipping Impact

The CryoCube F740 freezer is manufactured in Malden, Essex, United Kingdom.

Product Content

The steel used to manufacture the Eppendorf CryoCube® F740hiw ULT freezer contains almost 10% by weight of recycled content.

Packaging Content

The cardboard used to package the Eppendorf CryoCube® F740hiw ULT freezer contains recycled material resulting in over 65% by weight of recycled content in the packaging materials overall.

Energy Consumption

The Eppendorf CryoCube® F740hiw ULT is ENERGY Star certified and consumes 12.27 kWh per day (0.47 kWh per day per cubic foot). ENERGY Star tested the 115V version of the ULT freezer.

Water Consumption

The water-cooling system in the Eppendorf CryoCube® F740hiw ULT freezer is a closed-loop system. During manufacturing process, the heat exchanger is partially filled with water. The freezer is then connected to the end user’s chilled water system (water usage, if any, involved in the install will depend on the end user’s existing infrastructure); no additional water is added during the freezer’s use phase.

Lifetime Rating

The Eppendorf CryoCube® F740hiw ULT freezer has an estimated lifetime of 10 to 12 years.

Packaging End-of-Life

The cardboard and wooden pallets are readily recyclable in the United States. The other plastic packaging materials are recyclable, but the necessary recycling infrastructure is not readily available in most markets within the United States. Eppendorf does provide guidance to its customers on how to manage the packaging materials at end of life.

Product End-of-Life

Eppendorf will arrange for a recycling company to remove the old CryoCube® F740hiw ULT freezer. The company will then responsibly remove the refrigerant and recycle the bulk of the unit.

This category evaluates the steps that Eppendorf has taken to reduce energy consumption, water consumption, and / or waste generation at the manufacturing facility at which the Eppendorf CryoCube® F740hiw ULT freezer is made. The score of 6 in this category reflects Eppendorf’s efforts to reduce energy consumption at the facility.

Renewable Energy Use

The manufacturing facility at which the Eppendorf CryoCube® F740hiw ULT freezer is made does not use renewable energy.

Responsible Chemical Management

The score of 1 in this category reflects proof of an Environmental Health and Safety program and verified ISO 140001 processes. The refrigerants in the Eppendorf CryoCube® F740hiw ULT freezer were also found to be free of CMRs, PBTs, HCFCs, CFCs, GHS Category 1 Hazards, and red list chemicals.

Shipping Impact

The CryoCube F740 freezer is manufactured in Malden, Essex, United Kingdom.

Product Content

The steel used to manufacture the Eppendorf CryoCube® F740hiw ULT freezer contains almost 10% by weight of recycled content.

Packaging Content

The cardboard used to package the Eppendorf CryoCube® F740hiw ULT freezer contains recycled material resulting in over 65% by weight of recycled content in the packaging materials overall.

Energy Consumption

The Eppendorf CryoCube® F740hiw ULT is ENERGY Star certified and consumes 12.27 kWh per day (0.47 kWh per day per cubic foot). ENERGY Star tested the 115V version of the ULT freezer.

Water Consumption

The water-cooling system in the Eppendorf CryoCube® F740hiw ULT freezer is a closed-loop system. During manufacturing process, the heat exchanger is partially filled with water. The freezer is then connected to the end user’s chilled water system (water usage, if any, involved in the install will depend on the end user’s existing infrastructure); no additional water is added during the freezer’s use phase.

Lifetime Rating

The Eppendorf CryoCube® F740hiw ULT freezer has an estimated lifetime of 10 to 12 years.

Packaging End-of-Life

The cardboard and wooden pallets are readily recyclable in the United States. The other plastic packaging materials are recyclable, but the necessary recycling infrastructure is not readily available in most markets within the United States. Eppendorf does provide guidance to its customers on how to manage the packaging materials at end of life.

Product End-of-Life

Eppendorf will arrange for a recycling company to remove the old CryoCube® F740hiw ULT freezer. The company will then responsibly remove the refrigerant and recycle the bulk of the unit.