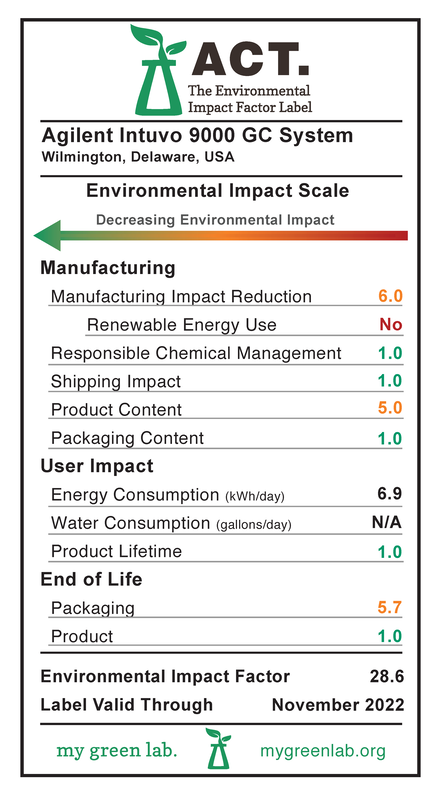

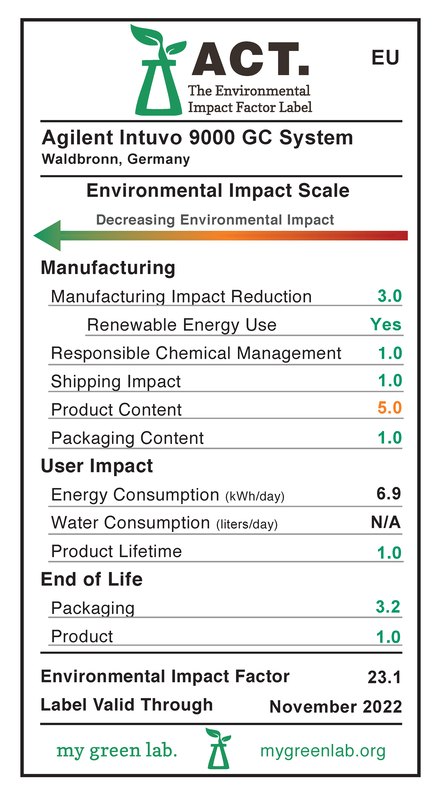

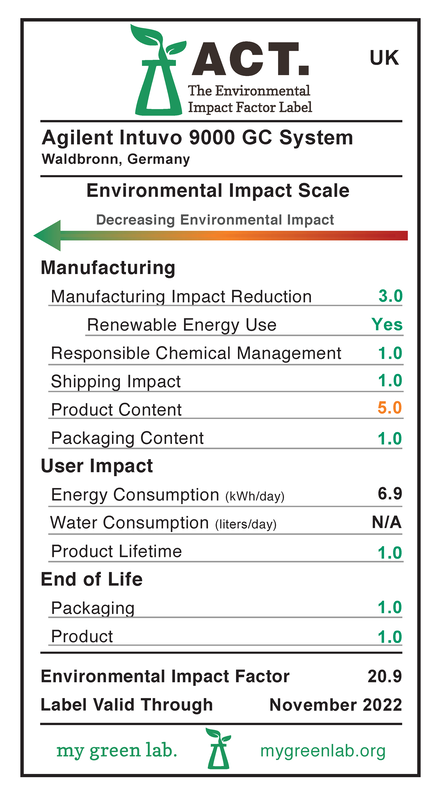

Agilent Intuvo 9000 GC System US/EU/UK

Additional Information about Agilent Intuvo 9000 GC System US/EU/UK

Manufacturing Impact Reduction

This Environmental Impact Factor evaluates the steps that have been taken to reduce energy, water, and waste at the Agilent manufacturing facilities. The Agilent Intuvo 9000 GC System is manufactured at the Delaware, USA and Waldbronn, Germany facilities for the US and EU/UK markets, respectively. The Delaware, USA facility has implemented measures to reduce its energy usage. The facility recently implemented an LED lighting retrofit involving 4,185 fixtures with an estimated energy savings of 1,755,603 kWh over the lifetime of the project. The Waldbronn, Germany facility has also implemented measures to reduce its energy and water usage. These initiatives, which include rain water harvesting, equipment replacement, and an upgraded, on-site combined heat and power plant, have resulted in energy and water reductions relative to a 2015 baseline. Note: European customers can choose to have the product manufactured at a different location but these additional facilities have not been audited. Instruments ordered in Europe have an zero cost option to be built at Waldbronn, Germany facility.

Renewable Energy Use

The Delaware, USA facility that manufacturers the Intuvo 9000 GC System for the US market does not utilize any renewable energy. The Waldbronn, Germany facility that manufacturers the Intuvo 9000 GC system for the EU & UK markets has a large photovoltaic system to support and offset electricity from the grid. The average capacity of the system is approximately 250 kWh per year. Note: European customers can choose to have the product manufactured at a different location but these additional facilities have not been audited. Instruments ordered in Europe have an zero cost option to be built at Waldbronn, Germany facility.

Responsible Chemical Management

Agilent has implemented policies and procedures to understand, manage and communicate hazardous chemistries throughout the value chain. Suppliers must ensure their raw materials comply with Agilent's General Specification for the Environment (GSE) which screens for hazardous chemistries such as EU REACH SVHCs and Proposition 65 chemicals. Further, the Agilent Intuvo 9000 GC System is EU RoHS compliant and the two manufacturing facilities that produce the product for US and EU/UK markets–the Delaware, USA and Waldbronn, Germany facilities, respectively–are ISO 14001 certified. Note: European customers can choose to have the product manufactured at a different location but these additional facilities have not been audited. Instruments ordered in Europe have an zero cost option to be built at Waldbronn, Germany facility.

Shipping Impact

For the US market, the Agilent Intuvo 9000 GC System is manufactured in Delaware, USA with its corresponding distribution center located in Memphis, TN. For the EU and UK markets, the Agilent Intuvo 9000 GC System is manufactured in Waldbronn, Germany with its corresponding distribution center located in Waghäusel, Germany. Note: European customers can choose to have the product manufactured at a different location but these additional facilities have not been audited. Instruments ordered in Europe have an zero cost option to be built at Waldbronn, Germany facility.

Product Content

The stainless steel components used in the Agilent Intuvo 9000 GC System contain recycled material resulting in almost 20% of recycled content in the overall product.

Packaging Content

The Agilent Intuvo 9000 GC System packaging materials include a cardboard box, poly-bag, and EPE foam. The cardboard box and EPE foam both contain recycled materials, resulting in over 60% of recycled content in the overall packaging system.

Energy Consumption

The Agilent Intuvo 9000 GC System consumes approximately 6.9 kWh per day during typical use. The energy consumption of the system was tested using the following methodology and parameters:

• Typical High Resolution Pesticide Analysis

• Inlet (MMI), 250C isothermal

• Oven program:

- 70C for 2min

- then 25C/min to 150C, no hold

- then 3C/min to 200C, no hold

- then 8C/min to 280C, 8 min hold

• Detector (FID), 280C isothermal

• Autoinjector (7693)

Water Consumption

The Agilent Intuvo 9000 GC System does not require water to function during its use phase.

Lifetime Rating

The Agilent Value Promise guarantees that the Agilent Intuvo 9000 GC System will have a usable lifetime of at least 10 years. Further, Agilent's guarantee to fix or replace the product while the model is still in production, coupled with Agilent's extended, guaranteed support, which lasts at least 7 years after end of production (as well as the option to purchase Agilent CrossLab Extended Services), demonstrates that Agilent's products can last upwards of 20 years with the proper care and maintenance.

Packaging End-of-Life

The Agilent Intuvo 9000 GC System packaging materials include a cardboard box, poly-bag and EPE foam. In the US market, the cardboard box is readily recyclable. The plastic packaging materials are either recyclable (but not readily recyclable since the necessary infrastructure is not readily available in the majority of the US market) or landfilled. In select EU member countries, Agilent participates in an Extended Producer Responsibility (EPR) scheme to support the take-back and responsible management of the packaging materials at their end-of-life. In the remaining EU countries, the cardboard box is readily recyclable while the plastic packaging materials are recycled, landfilled or incinerated via a waste-to-energy recovery process depending on the EU country and its available infrastructure. In the UK market, Agilent participates in an Extended Producer Responsibility (EPR) scheme to support the take-back and responsible management of the packaging materials at their end-of-life.

Product End-of-Life

Agilent has an active take-back program for its customers in the European Union, United Kingdom, and United States. Furthermore, Agilent encourages its customers to return the product at end-of-life by offering an incentive where the product can be traded-in for a refurbished model, new model, or a cash / credit balance.

This Environmental Impact Factor evaluates the steps that have been taken to reduce energy, water, and waste at the Agilent manufacturing facilities. The Agilent Intuvo 9000 GC System is manufactured at the Delaware, USA and Waldbronn, Germany facilities for the US and EU/UK markets, respectively. The Delaware, USA facility has implemented measures to reduce its energy usage. The facility recently implemented an LED lighting retrofit involving 4,185 fixtures with an estimated energy savings of 1,755,603 kWh over the lifetime of the project. The Waldbronn, Germany facility has also implemented measures to reduce its energy and water usage. These initiatives, which include rain water harvesting, equipment replacement, and an upgraded, on-site combined heat and power plant, have resulted in energy and water reductions relative to a 2015 baseline. Note: European customers can choose to have the product manufactured at a different location but these additional facilities have not been audited. Instruments ordered in Europe have an zero cost option to be built at Waldbronn, Germany facility.

Renewable Energy Use

The Delaware, USA facility that manufacturers the Intuvo 9000 GC System for the US market does not utilize any renewable energy. The Waldbronn, Germany facility that manufacturers the Intuvo 9000 GC system for the EU & UK markets has a large photovoltaic system to support and offset electricity from the grid. The average capacity of the system is approximately 250 kWh per year. Note: European customers can choose to have the product manufactured at a different location but these additional facilities have not been audited. Instruments ordered in Europe have an zero cost option to be built at Waldbronn, Germany facility.

Responsible Chemical Management

Agilent has implemented policies and procedures to understand, manage and communicate hazardous chemistries throughout the value chain. Suppliers must ensure their raw materials comply with Agilent's General Specification for the Environment (GSE) which screens for hazardous chemistries such as EU REACH SVHCs and Proposition 65 chemicals. Further, the Agilent Intuvo 9000 GC System is EU RoHS compliant and the two manufacturing facilities that produce the product for US and EU/UK markets–the Delaware, USA and Waldbronn, Germany facilities, respectively–are ISO 14001 certified. Note: European customers can choose to have the product manufactured at a different location but these additional facilities have not been audited. Instruments ordered in Europe have an zero cost option to be built at Waldbronn, Germany facility.

Shipping Impact

For the US market, the Agilent Intuvo 9000 GC System is manufactured in Delaware, USA with its corresponding distribution center located in Memphis, TN. For the EU and UK markets, the Agilent Intuvo 9000 GC System is manufactured in Waldbronn, Germany with its corresponding distribution center located in Waghäusel, Germany. Note: European customers can choose to have the product manufactured at a different location but these additional facilities have not been audited. Instruments ordered in Europe have an zero cost option to be built at Waldbronn, Germany facility.

Product Content

The stainless steel components used in the Agilent Intuvo 9000 GC System contain recycled material resulting in almost 20% of recycled content in the overall product.

Packaging Content

The Agilent Intuvo 9000 GC System packaging materials include a cardboard box, poly-bag, and EPE foam. The cardboard box and EPE foam both contain recycled materials, resulting in over 60% of recycled content in the overall packaging system.

Energy Consumption

The Agilent Intuvo 9000 GC System consumes approximately 6.9 kWh per day during typical use. The energy consumption of the system was tested using the following methodology and parameters:

• Typical High Resolution Pesticide Analysis

• Inlet (MMI), 250C isothermal

• Oven program:

- 70C for 2min

- then 25C/min to 150C, no hold

- then 3C/min to 200C, no hold

- then 8C/min to 280C, 8 min hold

• Detector (FID), 280C isothermal

• Autoinjector (7693)

Water Consumption

The Agilent Intuvo 9000 GC System does not require water to function during its use phase.

Lifetime Rating

The Agilent Value Promise guarantees that the Agilent Intuvo 9000 GC System will have a usable lifetime of at least 10 years. Further, Agilent's guarantee to fix or replace the product while the model is still in production, coupled with Agilent's extended, guaranteed support, which lasts at least 7 years after end of production (as well as the option to purchase Agilent CrossLab Extended Services), demonstrates that Agilent's products can last upwards of 20 years with the proper care and maintenance.

Packaging End-of-Life

The Agilent Intuvo 9000 GC System packaging materials include a cardboard box, poly-bag and EPE foam. In the US market, the cardboard box is readily recyclable. The plastic packaging materials are either recyclable (but not readily recyclable since the necessary infrastructure is not readily available in the majority of the US market) or landfilled. In select EU member countries, Agilent participates in an Extended Producer Responsibility (EPR) scheme to support the take-back and responsible management of the packaging materials at their end-of-life. In the remaining EU countries, the cardboard box is readily recyclable while the plastic packaging materials are recycled, landfilled or incinerated via a waste-to-energy recovery process depending on the EU country and its available infrastructure. In the UK market, Agilent participates in an Extended Producer Responsibility (EPR) scheme to support the take-back and responsible management of the packaging materials at their end-of-life.

Product End-of-Life

Agilent has an active take-back program for its customers in the European Union, United Kingdom, and United States. Furthermore, Agilent encourages its customers to return the product at end-of-life by offering an incentive where the product can be traded-in for a refurbished model, new model, or a cash / credit balance.